This build was inspired by a design posted on YouTube by SM. I'll try to find the original later and post a link. For now, here is a short clip of my ATS in action (pump shut off).

<iframe width="420" height="315" src="http://www.youtube.com/embed/w94osKXtwow" frameborder="0" allowfullscreen></iframe>

http://youtu.be/w94osKXtwow

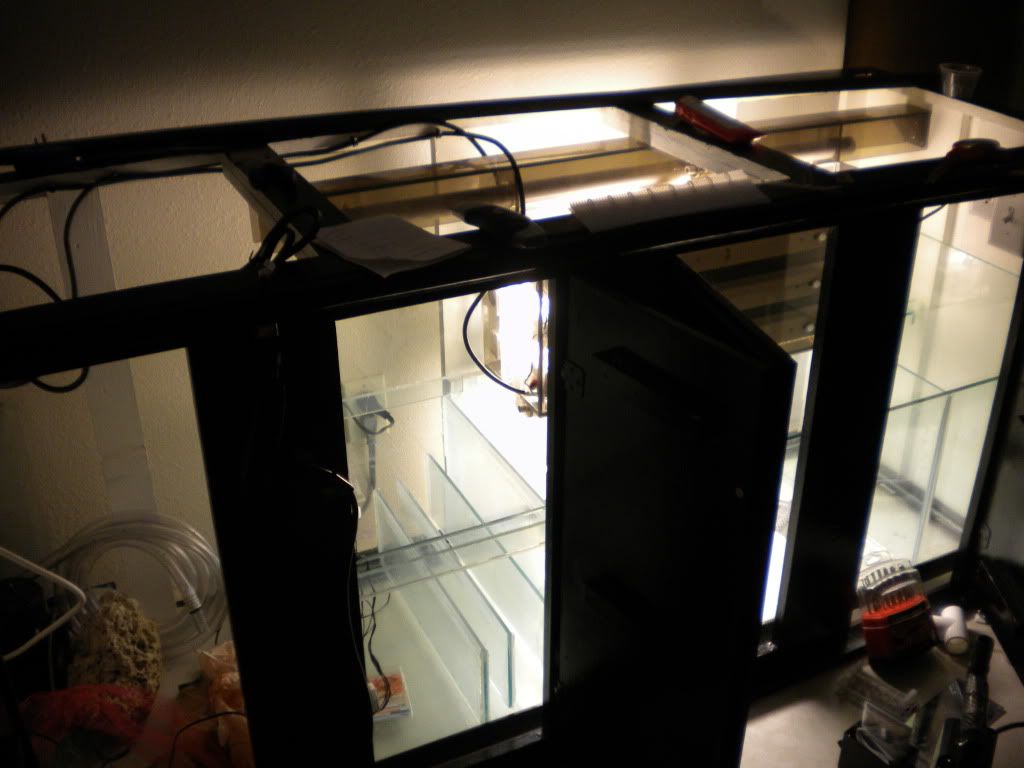

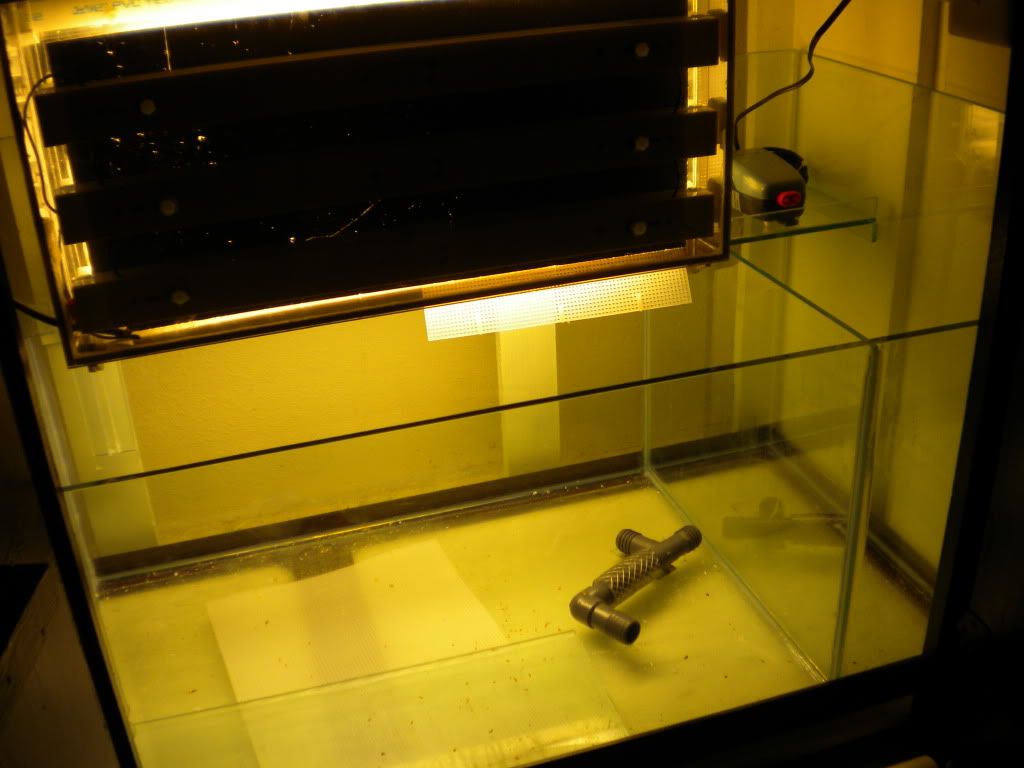

The ATS resides in my tanks stand above the sump. The side loading feature allows it to fit and function in the limited space available. In designing it, I first chose the lights and then built the scrubber around them.

Reply With Quote

Reply With Quote