Hi Guys,

I have been working on a new hybrid horizontal/vertical ATS design for a scrubbing sump... or a "SCRUMP" as I like to call it, if you will. I plan on producing these shortly, in order to take the place of my Vortex Needle Wheel Protien Skimmers which are being taken down from my site soon. Since I need to replace my water treatment products anyways, and I really like the scrubbers, why not offer the "Victory V Scrump" on my site? http://www.nautilusreef.com

I have been running a version of ATS for about 2 mos, and have been skimmerless for 4weeks now, and am very happy with the ATS concept and performance so for. I have been running my prototype Victory Scrump for about 3 weeks now to prove the concept and it's working VERY well. (Pictures/diagrams coming... see below) My corals are healthier than EVER, Two of MY RIC's that were dying going clear, are now SPLITTING? after removing the skimmer? Im amazed actually at how well my other softies are doing too. In my case, I might not be typical though, as I think i was OVERSKIMMING my tank with my larger skimmers i build and sell removing the good stuff with the badHaving studied ATS for awhile, I like the features that a Vertical Screens offer, (double sided very good use of space) but I dont like the requirement of lighting it from BOTH SIDES. The HORIZONTAL method is less efficient use of space (one sided) but it allows for good cascade of the flow, different water spray options and design options, and (I think) better lighting options, which is being able to successfully light it from above vs the sides...

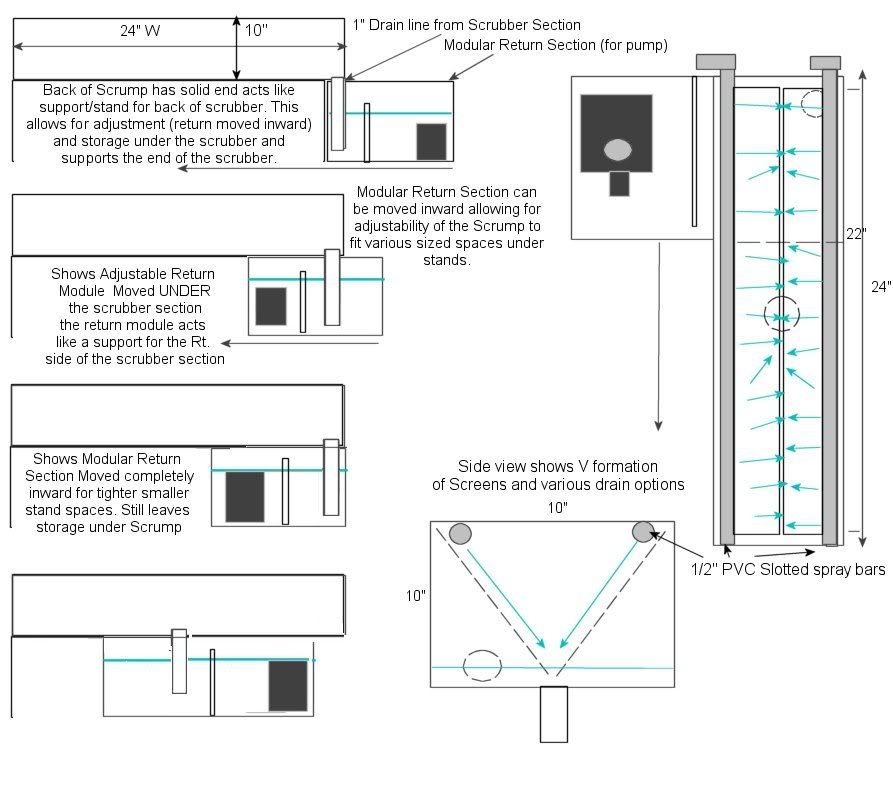

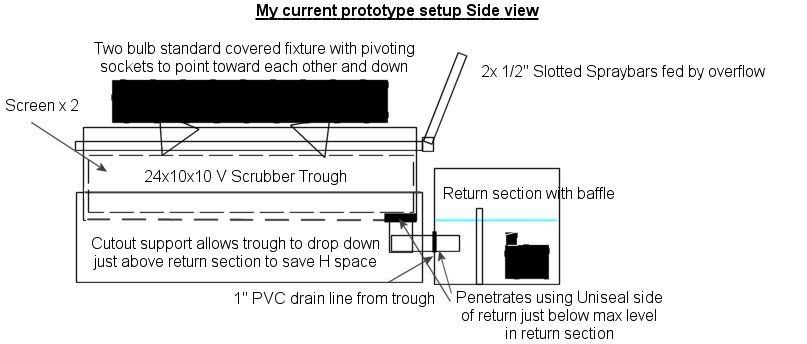

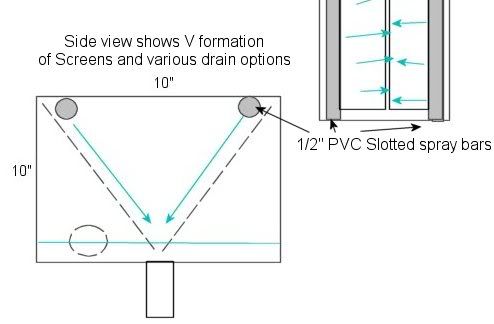

I think I have solved this problem by coming up with the "Victory V Scrump" A Hybrid Design/method for the placment of the screens... Place the screens ANGLED inwards in V shape in a long trough along each side With lights placed ABOVE them. This is why I call my design the "VICTORY Scrubber Scrump" I was trying to figure out a way to maximize surface area, and I came up with the "V" shape of the screens along the sides of the trough, this utilizes EVERY inch of the trough and sheets while still being able to light it from above like a horizontal scrubber. The trick was to figure a way to allow lights to be placed ABOVE them without having to have them on each side like a TWO sided scrubber. I think I found it with the "V" design. The V shape placement of the screens allows for large sheets to be placed along the full 24" of the trough, but angled INWARD towards the center of the trough, which does two things..

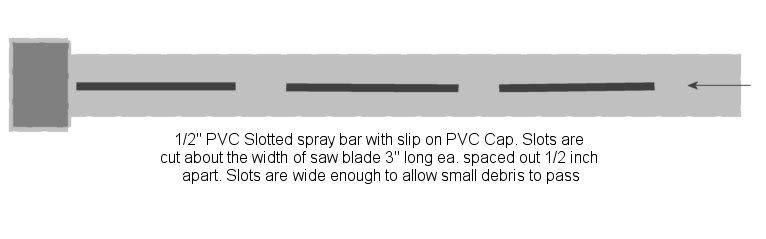

1. The angled sheets are semi-horizontal in that, the water sprayed from above cascades downward across the sheets face, which meanwhile are exposed to lighting on the entire surface area. The sheets DO NOT have to be placed inside the PVC pipe to support them or power them, they rest on the sides of the trough the slotted spray bars trickle down over them, to clean them is a breeze, simply tilt them out and back in for cleaning.

2. It allows the lighting to come down from ABOVE vs the sides. The V shape angles and exposes the screen surface material towards the lights even when the lighting is placed directly above them, they still get excellent lighting coverage.

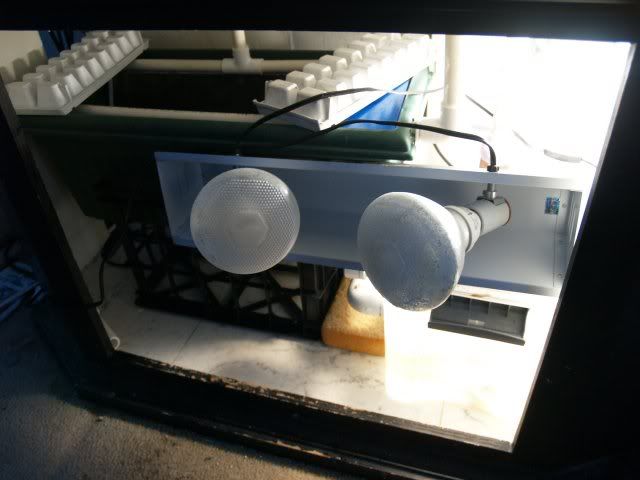

For the Prototype trough I just purchased a flower box and modded it supported it with cutout plastic eggcrate to lower it, (my stand is short) and used Rubbermaid container for return, and fixture is Reptile light with two angled screw in bases with 2x 25w CPF floods

Here is how I setup my current prototype (will get some pix up shortly) Im using 2 ea 25W Floods in fixture

here's more

With light removed looking at one of the screens and PVC plumbing

One side of 20"L x 8" H mesh screen ready for first cleaning after 12 days

My Scrump Design does a few things I think are critical to success... It has large surface area for the ATS sheets, its easy to acess/clean, and be lighted with simple lights or with a variety of avaialable fixtures, with one huge difference, it will NOT be lighted from the sides but from ABOVE. It can be powered (as in my case) from the overflow(s) or an external pump.

And most importantly to me the EFFICIENCY of this Hybrid ATS scrubber: With this Design: The surface area of screens with this V design is = to that of a Vertical double sided Scrubber going the length of the trough

Reply With Quote

Reply With Quote